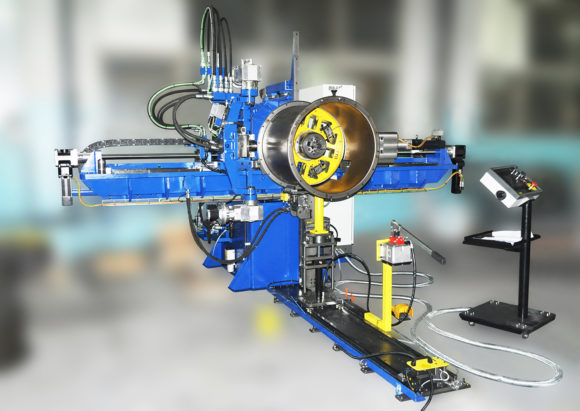

Last year "Ventilation Systems" made a record number of crucial upgrades to its process equipment fleet. Following the recent launch of the new thermoplastic processing machines and the servo robot we are happy to announce yet another addition to the fleet – a state-of-the-art flanging machine with a punching press tool made in EU.

The latest addition being part of the company's long-term policy of continuous upgrading its production equipment fleet reflects the commitment of "VENTS" to the highest quality standards. The launch of the new flanging machine marks another step towards boosting product quality and production output. In particular, the machine will serve the factory lines producing VPVO, TT Pro axial fans and other models.

The new machine is custom-built to fabricate the outer frames of axial fans and air ducts in large numbers. The machine combines flanging and punching functions which are completely automated. The operations are performed with extreme precision without re-positioning the blanks.

According to "VENTS" engineers, the test runs of the new machine went as planned achieving the desired accuracy as well as high performance and operation safety. This multifunctional machine is operator-friendly and easy to program offering excellent adaptability to the future needs. The operation sequence is controlled via an electronic panel with a programmable logical controller and a touchscreen control panel.