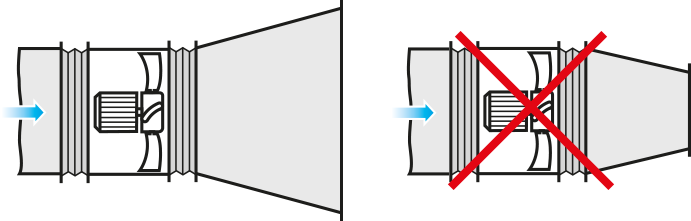

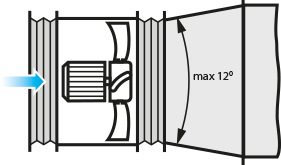

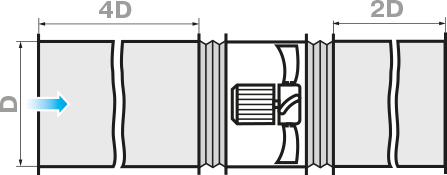

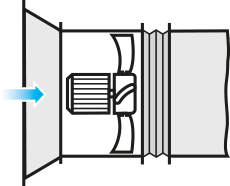

If the axial fan is a terminal device of the ventilation system (i.e. there is no downstream ducting) the unit must be equipped with a diffuser to reduce the air flow velocity and the fan dynamic pressure. Reduction of the air discharge velocity results in a significant reduction of shock losses which are proportional to the square of velocity decrement.

The fan should not be equipped with a downstream contractor.