At the end of March 2020 the company “Ventilation systems” put the latest modification of the bending machine TRUMPF TruBend 5085 into operation. The product line extension, constant output growth, and desire to contribute to a comfortable working environment for the staff were the reasons for it.

The VENTS metalware shop seems to have broken all records by putting the largest number of new production equipment items into service for the last year. Apparently, this year the shop is going to become a record holder in modernization again, as the new press brake will surely be not the last new piece of equipment there. In particular, we are planning to install an assembly machine for inserting rubber, a machine for angle joints forming, two hydraulic deep drawing presses, consoles for presses and guideways for them.

It is worth recalling that TRUMPF TruBend 5085 is a high-tech hydraulic press for metal sheets bending. The ACB laser allows precise measuring and adjusting of a bending angle by the machine. It usually takes only 12 seconds to process one part. The work area is equipped with indicators and cameras displaying the sheets bending process on the screen. This allows a machine operator to insert parts properly.

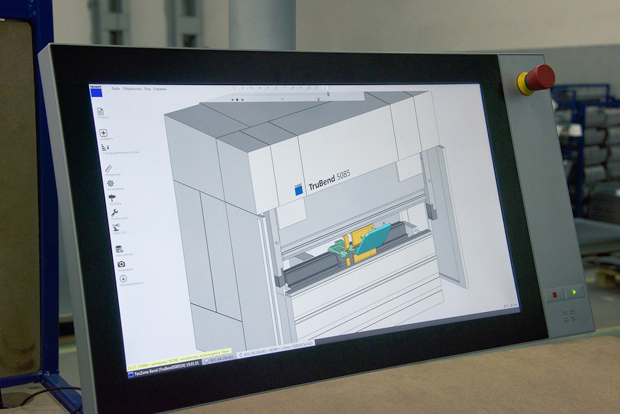

TRUMPF TruBend 5085 has updated software for better bending process adjustment. Due to the touch screen monitor a machine operator can create a three dimensional model of production process and easily adjust bending operations right in the process of the unit bending. Metalware manufacturing became more precise and comfortable due to 3D modeling of the production process.