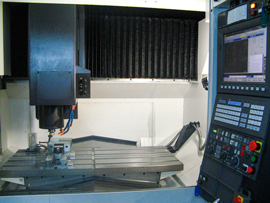

Every year brings more and more technology advances and innovations, new product offerings and product quality improvements. To cater for the steadily growing portfolio of orders both in the home and international markets VENTS decided to upgrade its process equipment with an Okuma CNC machining centre for high-speed and high-precision metal processing.

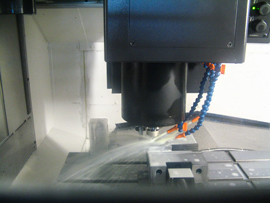

This highly skilled metal processing warrior Okuma is capable of grinding, drilling and boring operations replacing 3 dedicated mills and rendering them obsolete. The machine features a thermally stable and rigid cast bed which ensures consistent processing precision for years to come while a host of intelligent functions takes metal processing quality, performance and speed to an entirely new level. The upgrade has already reduced the time required for machining dies and pressure moulds while our partners are now getting the best ventilation products from VENTS much faster than before.

Roman Kravchenko, a process programming engineer

Roman Kravchenko, a process programming engineer

"The technical capabilities of the new Okuma unit put our state-of-the-art cutting tools to best use leading to significant savings of resources. Since the machining centre is used for manufacturing tooling to exact specifications - in particular, the pressure mould parts - high precision is a key factor of the equipment efficiency. In this regard the new Okuma unit is light years ahead of the outgoing equipment. The machine follows a pre-programmed sequence automatically for improved precision and speed as well as lower chance of error.

In addition to that high speed and precision minimise the part processing time and boost the production efficiency several-fold", says Roman Kravchenko, a process programming engineer.