| Unit of measurement | VUT 300 E2V EC | |

| Connected air duct size | mm | 150 |

| Phases | - | 1 |

| Minimum supply voltage | V | 230 |

| Maximum supply voltage | V | 230 |

| Power supply frequency | Hz | 50 |

| Rated power | W | 212 |

| Power of electrical reheater | W | 4000 |

| Unit current | A | 18.8 |

| Maximum airflow | m3/h | 300 |

| Sound pressure level LpA at 3 m | dB(A) | 37 |

| Heat recovery efficiency, max | % | 95 |

| Heat exchanger type | - | Counter flow |

| Heat exchanger material | - | Polystyrene |

| Weight | kg | 38 |

| Extract filter | - | G4 |

| Supply filter | - | G4 (F7 option) |

| Transported air temperature (max) | °С | 60 |

| Transported air temperature (min) | °С | -39 |

| Ambient air temperature min | °С | 1 |

| Ambient air temperature max | °С | 40 |

| Ambient air humidity max | % | 80 |

| Ingress protection rating | - | IP22 |

| Ingress protection rating of the drive | - | IP44 |

| Trademark | Vents | |||||

| Model | VUT 300 E2V EC | |||||

| Specific energy consumption (SEC) (kWh/(m2/a)) | Cold | Average | Warm | |||

| -78.6 | A+ | -39.3 | A | -14.1 | E | |

| Type of ventilation unit | Bidirectional | |||||

| Type of drive installed | Variable speed | |||||

| Type of heat recovery system | Recuperative | |||||

| Thermal efficiency of heat recovery (%) | 89 | |||||

| Maximum flow rate (m3/h) | 270 | |||||

| Electric power input (W) | 205 | |||||

| Reference flow rate (m3/s) | 0.053 | |||||

| Reference pressure difference (Pa) | 50 | |||||

| Specific power input (SPI) (W/(m3/h)) | 0.529 | |||||

| Control typology | Local demand control | |||||

| Maximum internal leakage rates (%) | 2.7 | |||||

| Maximum external leakage rates (%) | 2.7 | |||||

| Declared typology | RVU BVU | |||||

| Sound power level (dB(A)) | 57 | |||||

| The annual electricity consumption (AEC) (kWh/a) | Cold | Average | Warm | |||

| 862 | 325 | 280 | ||||

| The annual heating saved (AHS) (kWh/a) | Cold | Average | Warm | |||

| 9141 | 4673 | 2113 | ||||

| Name | Photo | Description |

|---|---|---|

| Vents SR 150/600 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SR 150/900 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SR 150/1200 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SRF 150/600 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Vents SRF 150/900 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Vents SRF 150/2000 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Name | Photo | Description |

|---|---|---|

| Vents KOM 150 |

|

Backdraught damper with spring-loaded plates for shutting off air flow in round air ducts |

| Vents KOMu 150 |

|

Backdraught damper with spring-loaded plates for shutting off air flow in round air ducts |

| Name | Photo | Description |

|---|---|---|

| Vents CO2-1 |

|

CO2 sensors |

| Vents CO2-2 |

|

CO2 sensors |

| Name | Photo | Description |

|---|---|---|

| Vents Belimo LF24 |

|

The Belimo LF series actuators are designed for controlling air dampers with cross section up to 0.8 m² performing protection functions |

| Vents Belimo LF230 |

|

The Belimo LF series actuators are designed for controlling air dampers with cross section up to 0.8 m² performing protection functions |

| Vents Belimo TF24 |

|

The actuators are designed for controlling air dampers with cross section up to 0.4 m² performing protection functions |

| Vents Belimo TF230 |

|

The actuators are designed for controlling air dampers with cross section up to 0.4 m² performing protection functions |

| Name | Photo | Description |

|---|---|---|

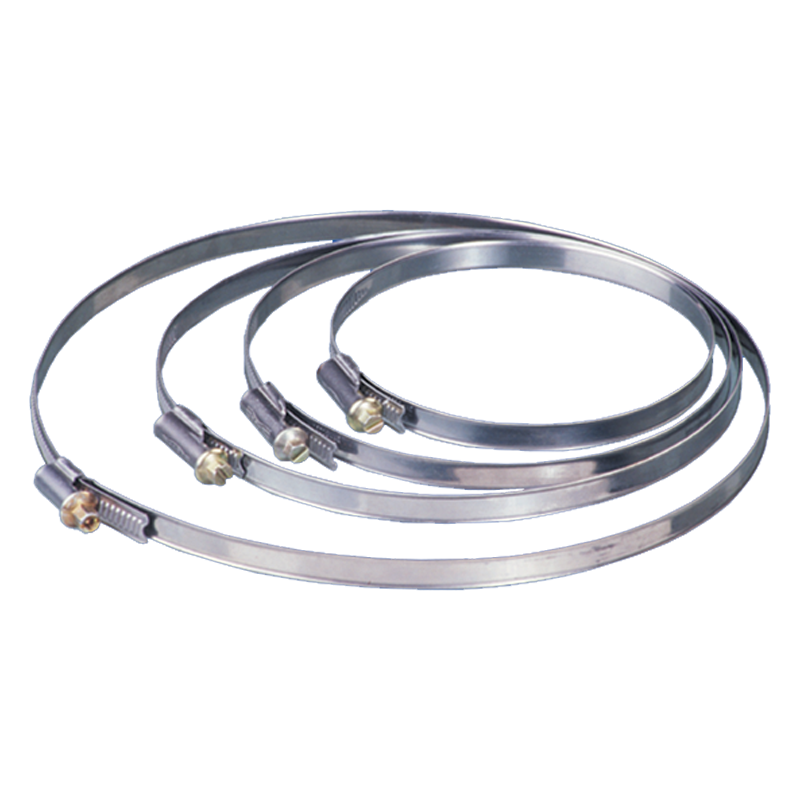

| Vents C 150 |

|

The clamps are designed for quick and reliable mounting and connection of various round ventilation system components. Clamps are made of stainless and galvanized steel band |