| Unit of measurement | VUT 300 H2 mini EC A14 | |

| Connected air duct size | mm | 125 |

| Minimum supply voltage | V | 230 |

| Maximum supply voltage | V | 230 |

| Power supply frequency | Hz | 50/60 |

| Rated power | W | 165 |

| Unit current | A | 1.3 |

| Maximum airflow | m3/h | 300 |

| Sound pressure level LpA at 3 m | dB(A) | 33 |

| Heat recovery efficiency, max | % | 79 |

| Heat exchanger type | - | Cross flow |

| Heat exchanger material | - | Polystyrene |

| Weight | kg | 32 |

| Extract filter | - | G4 |

| Supply filter | - | G4, F8 |

| Transported air temperature (max) | °С | 60 |

| Transported air temperature (min) | °С | -25 |

| Ambient air temperature min | °С | 1 |

| Ambient air temperature max | °С | 40 |

| Ambient air humidity max | % | 80 |

| Ingress protection rating | - | IP22 |

| Ingress protection rating of the drive | - | IP44 |

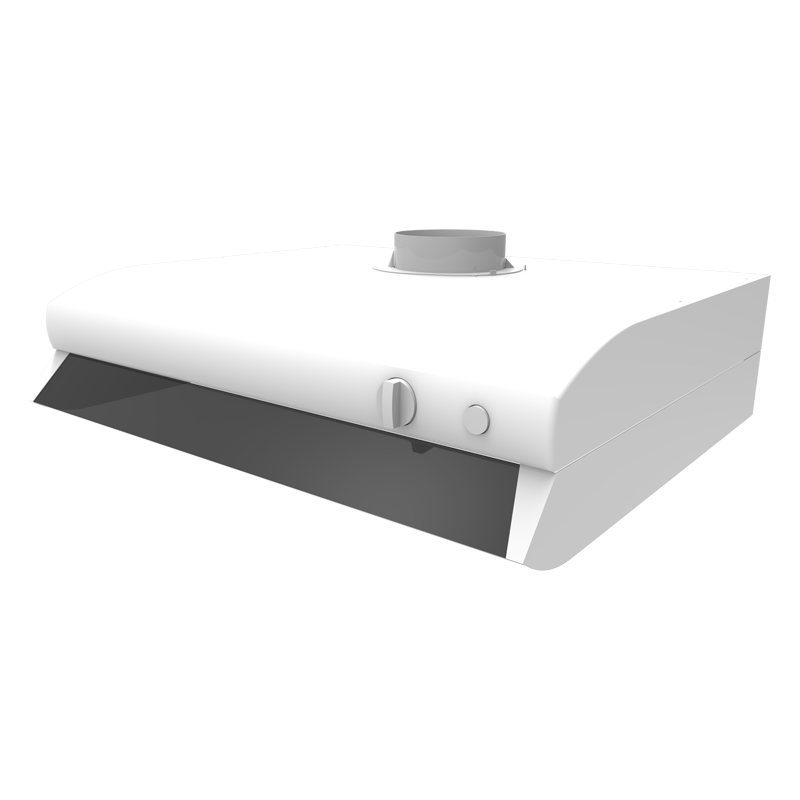

| Trademark | Vents | |||||

| Model | VUT 300 H2 mini EC A14 | |||||

| Specific energy consumption (SEC) (kWh/(m2/a)) | Cold | Average | Warm | |||

| -70.5 | A+ | -36.6 | A | -14.5 | E | |

| Type of ventilation unit | Bidirectional | |||||

| Type of drive installed | Variable speed | |||||

| Type of heat recovery system | Recuperative | |||||

| Thermal efficiency of heat recovery (%) | 62 | |||||

| Maximum flow rate (m3/h) | 250 | |||||

| Electric power input (W) | 150 | |||||

| Reference flow rate (m3/s) | 0.044 | |||||

| Reference pressure difference (Pa) | 50 | |||||

| Specific power input (SPI) (W/(m3/h)) | 0.313 | |||||

| Control typology | Local demand control | |||||

| Maximum internal leakage rates (%) | 2.7 | |||||

| Maximum external leakage rates (%) | 2.7 | |||||

| Declared typology | RVU BVU | |||||

| Sound power level (dB(A)) | 53 | |||||

| The annual electricity consumption (AEC) (kWh/a) | Cold | Average | Warm | |||

| 747 | 210 | 165 | ||||

| The annual heating saved (AHS) (kWh/a) | Cold | Average | Warm | |||

| 8047 | 4114 | 1860 | ||||

| Name | Photo | Description |

|---|---|---|

| Vents HV2 |

|

Humidity sensor |

| Vents CO2-1 |

|

CO2 sensors |

| Vents CO2-2 |

|

CO2 sensors |

| Vents HR-S |

|

Electro-mechanical humidistat |

| Name | Photo | Description |

|---|---|---|

| Vents SR 125/600 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SR 125/900 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SR 125/1200 |

|

Silencers made of galvanized steel filled with non-combustible sound-absorbing material |

| Vents SRF 125/600 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Vents SRF 125/900 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Vents SRF 125/2000 |

|

Silencers made of aluminium alloy filled with non-combustible sound-absorbing material |

| Name | Photo | Description |

|---|---|---|

| Vents KOM 125 |

|

Backdraught damper with spring-loaded plates for shutting off air flow in round air ducts |

| Vents KRV 125 |

|

Air dampers for automatic air flow control in round ducts |

| Name | Photo | Description |

|---|---|---|

| Vents SH-32 |

|

Hydraulic U-trap to drain condensate from heat exchangers and coolers |

| Name | Photo | Description |

|---|---|---|

| Vents Belimo LF230 |

|

The Belimo LF series actuators are designed for controlling air dampers with cross section up to 0.8 m² performing protection functions |

| Name | Photo | Description |

|---|---|---|

| Vents SF 240x184x40 G4 |

|

Panel filter G4 |

| Vents SF 240x184x40 F8 |

|

F8 panel filter |

| Name | Photo | Description |

|---|---|---|

| Vents KH-1 |

|

Kitchen hood for removing combustion products, vapors and odors from the air |