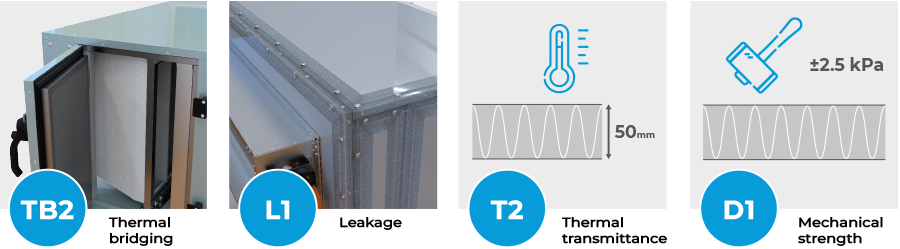

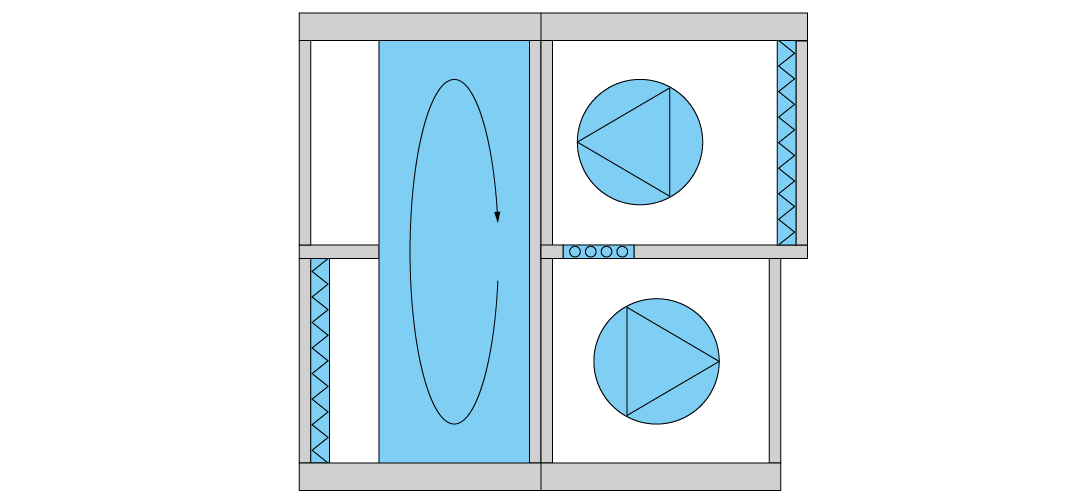

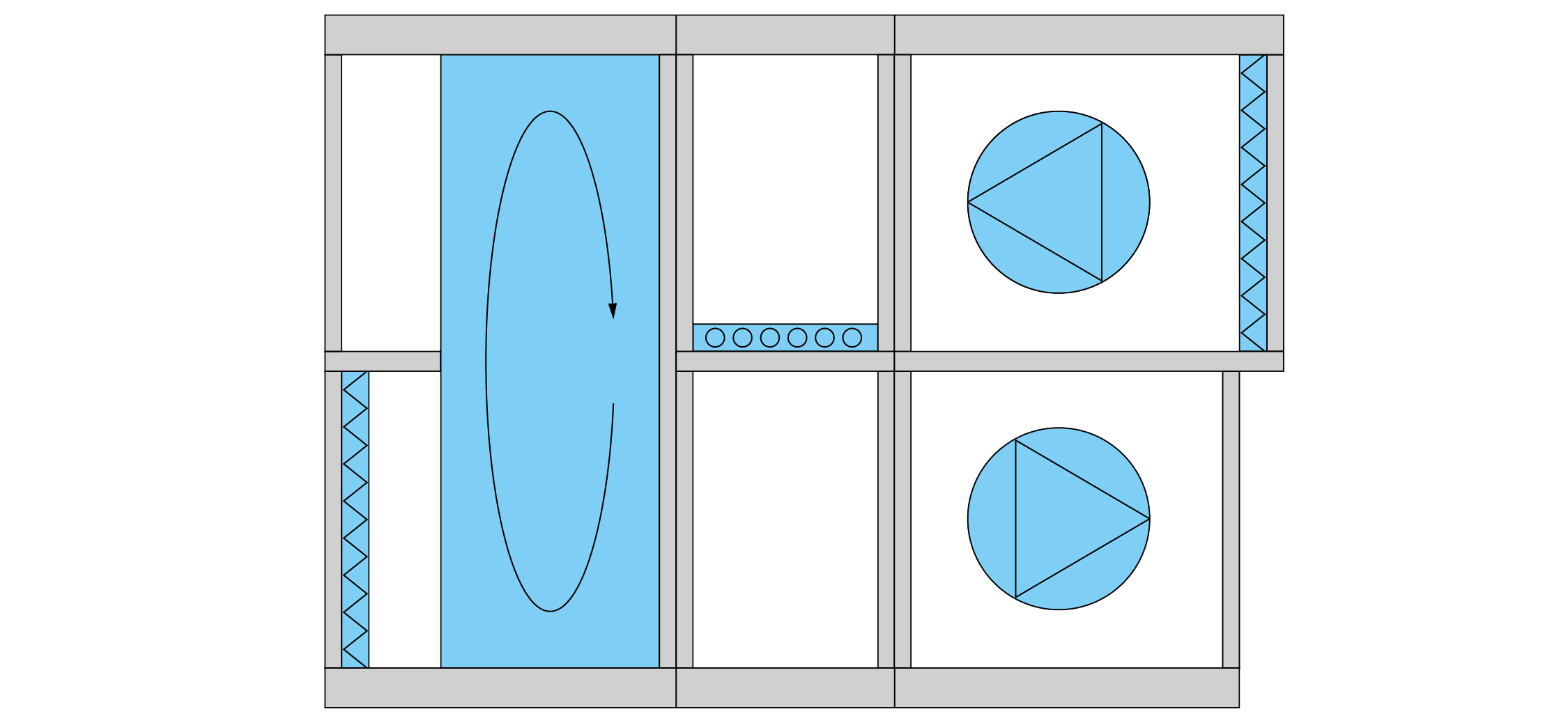

T2 / TB2 / L1 / D1

The construction of the case with a PVC profile ensures the absence of thermal bridges, minimizes heat loss and reduces the noise level.

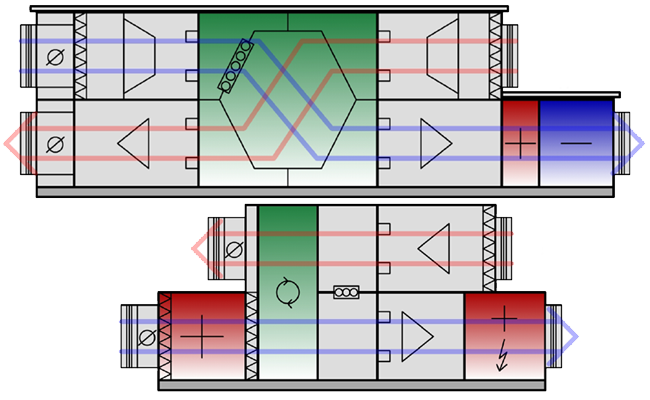

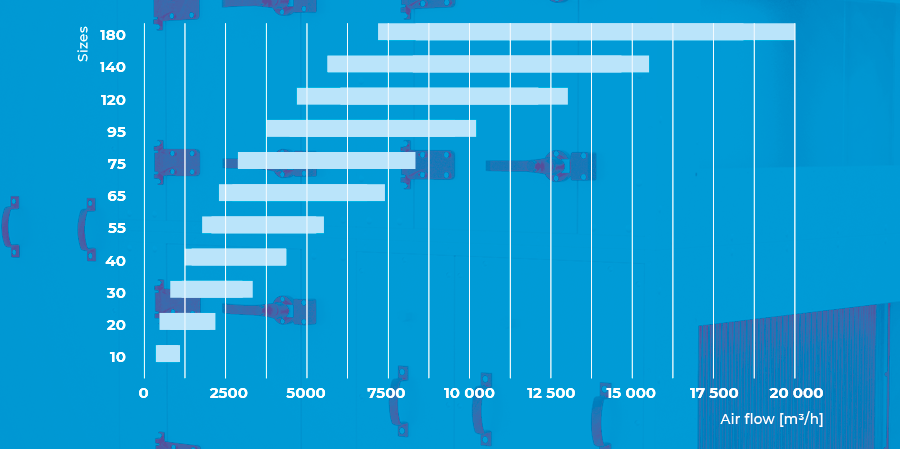

| Size | Nominal air flow, m3/h | Instalation type | Heat exchanger material | Unit location | Service side | Energy-saving features |

| AVS10 | 1000 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS20 | 2050 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS30 | 3000 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS40 | 3950 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS55 | 5400 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS65 | 6800 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS75 | 7550 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS95 | 9350 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS120 | 11850 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS140 | 14150 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS180 | 18200 | horizontal | polystyrene/

aluminum | indoor/

outdoor | Left/

Right | T2/TB2 |

| Size | Nominal air flow, m3/h | Instalation type | Heat wheel type | Unit location | Service side | Energy-saving features |

| AVS10 | 1000 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS20 | 2050 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS30 | 3000 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS40 | 3950 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS55 | 5400 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS65 | 6800 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS75 | 7550 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS95 | 9350 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS120 | 11850 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS140 | 14150 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |

| AVS180 | 18200 | horizontal | condensation/ enthalpy/ sorption | indoor/

outdoor | Left/

Right | T2/TB2 |