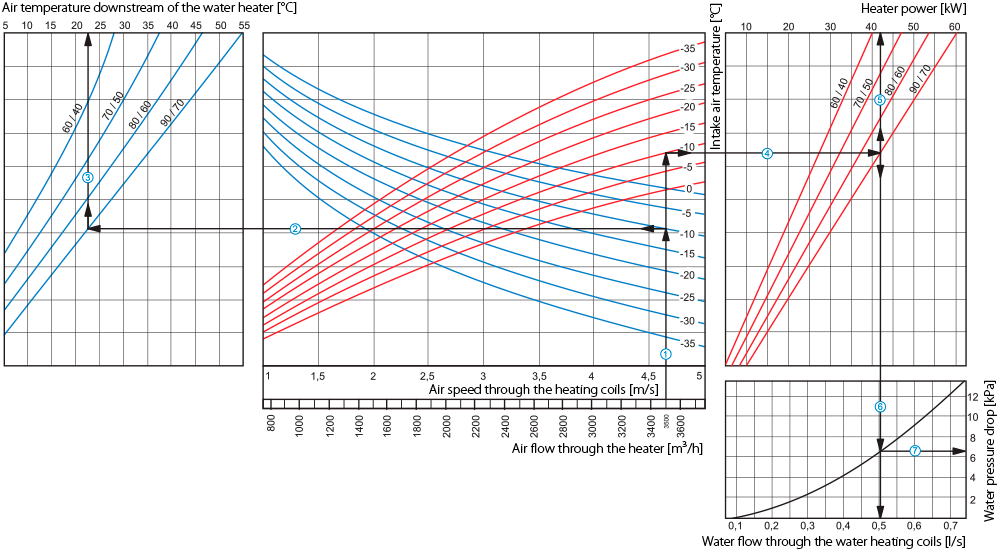

Air Speed. Starting from 3500 m

3/h on the air flow scale draw a vertical line ① till the air speed axis which makes 4.65 m/s.

- Supply air temperature. Prolong the line ① of air flow up to the point where it crosses the outside air temperature (-10°C); then draw a horizontal line ② from this point to the left till crossing water in/out temperature curve (90/70). From this point draw a vertical line ③ to the supply air temperature axis on top of the graphic (+22.5 °C).

- Heating capacity. Prolong the line ① up to the point where it crosses the outside air temperature (red line, -10°C) and draw a horizontal line ④ from this point to the right until it crosses water in/out temperature curve (90/70), from here draw a vertical line ⑤ up to the scale representing the heating coil capacity (42.0 kW).

- Water flow. Prolong the line down to water flow axis at the bottom of the graphic ⑥ (0.5 l/s).

- Water pressure drop. Draw the line ⑦ from the point where line ⑥ crosses the black curve to the pressure drop axis. (6.5 kPa).