The sound-insulated dual-purpose smoke extraction fan is used in emergency exhaust ventilation systems for forced extraction of smoke, heated gases and combustion products.

May be used in general exhaust ventilation systems in shopping centers, offices, garages, warehouses, and kitchens.

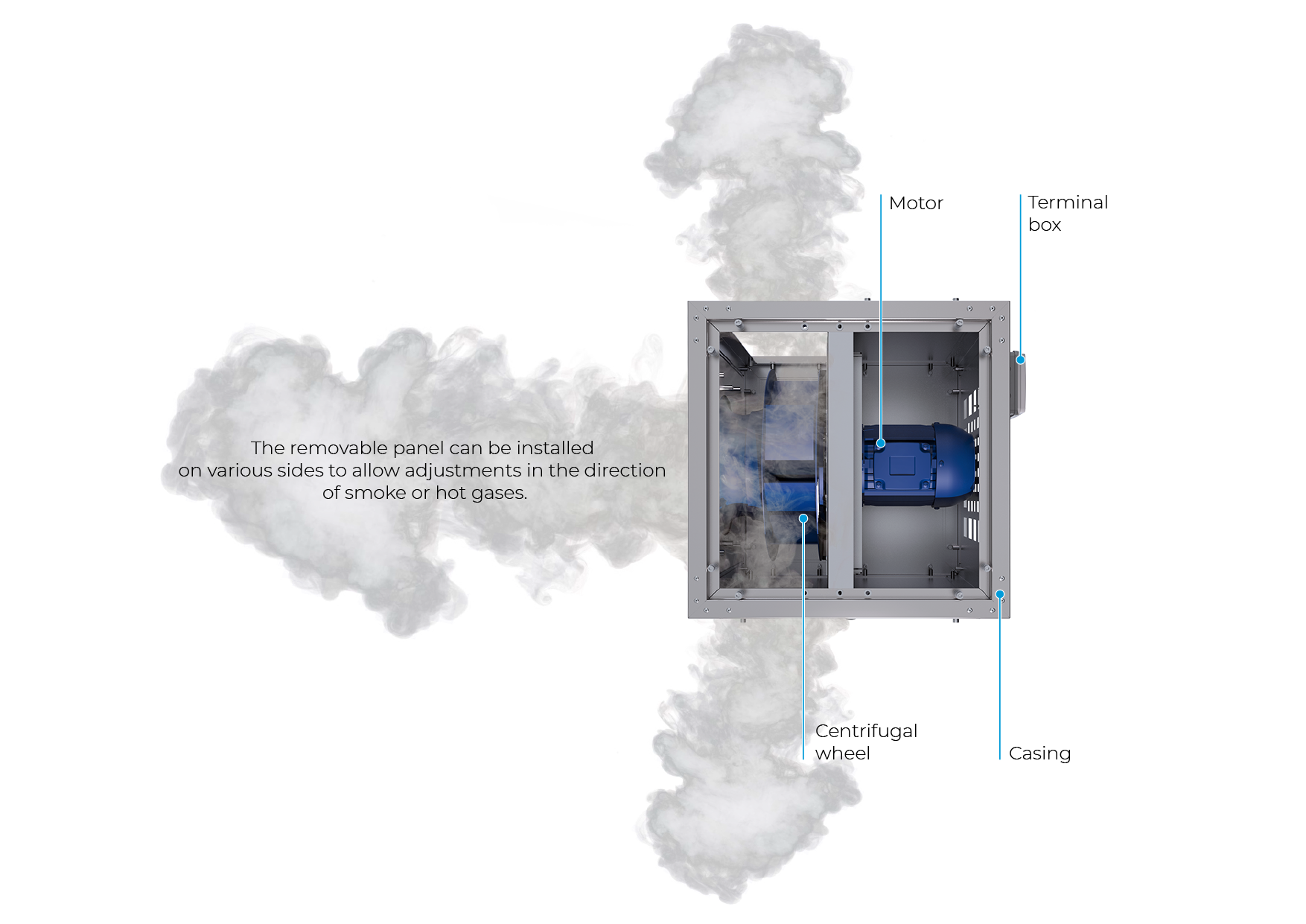

The fan casing is made of an aluminum frame fastened with aluminum corners and removable heat and sound insulating double-layer panels made of galvanized steel.

The panels are insulated with 20 mm thick non-flammable mineral wool.

The impeller with backward-curved blades is powder coated.

The connecting spigots, which also serve as anti-vibration dampers, can be of square or round cross-section.

The round connecting spigots are equipped with rubber seals.

The connecting spigots are not included in the delivery set and must be ordered separately.

The direction of air flow and air mixtures is controlled by rearranging the panels on the fan frame.

The fan is equipped with a single-phase (up to 1.1 kW) or three-phase electric motor designed for 220/400 V voltage.

The electric motor is installed outside the air flow on an additional panel inside the fan.

The motor ingress protection rating according to IEC 60034-5 is IP55.

|

Air flow: up to 28 500 m³/h. |

|

Operational temperature: |

The fan is designed to extract smoke and air mixtures heated up to +400 °C for up to 120 minutes, and long-term operation with transported air temperature of up to +120 °C.

The fan can be equipped with a frequency converter for speed control.

The fan can be manufactured for temperate (U), cold (HL), tropical (T) or marine moderately cold (M) climates of the first placement category.

The fan is installed with a square or round air duct.

The connection to the air ducts is carried out by means of a flexible joint or an adapter joint of the appropriate cross-section.

The fan is powered through the external terminal box.

The fan can be installed in any position according to the direction of air flow, provided that access for maintenance is ensured.