VENTS has recently updated its family of centrifugal axial fans with a new model equipped with an energy-saving EC motor in a plastic casing. The new model VENTS VK EC producing up to 1,500 m3/h per hour is intended for supply and extract ventilation of small spaces with elevated humidity levels offering an exciting combination of energy efficiency and flexible control. The VENTS VK EC fans help reduce energy consumption by a dramatic 35% for significant operating cost savings.

The fans are built around highly efficient electronically commutated (EC) motors which run at up to 90% efficiency and help achieve excellent aerodynamic performance and low noise levels.

Another key advantage of EC motors is optimum control over the entire speed range. The motor output is regulated based on a number of control factors such as temperature, pressure, smoke content and parameters. Upon application of a control factor an EC fan changes its speed to supply the exact amount of air required for the ventilation system at the given time. To make control even more flexible the fans can be combined into a single computer network.

Reliability and extended lifetime

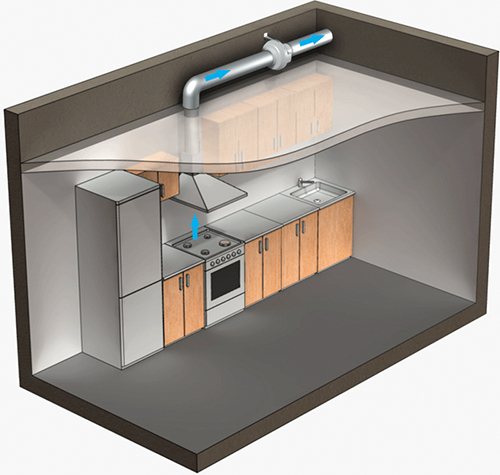

The fan casing is made of high-quality ABS plastic which, unlike metal, does not corrode. This makes VENTS VK EC fans an optimum choice for extract ventilation systems of spaces with elevated humidity levels (such as bathrooms or kitchens). The motors utilize roller bearings for an extra long service life (40,000 hours).

Convenient installation

The fans are compatible with round air ducts 100, 125, 150, 200, 250 and 315 mm in diameter and can be installed into the ductwork at any point at any angle. The VK EC fans are supplied with a mounting bracket for easy removal of the fan (e.g. for cleaning).