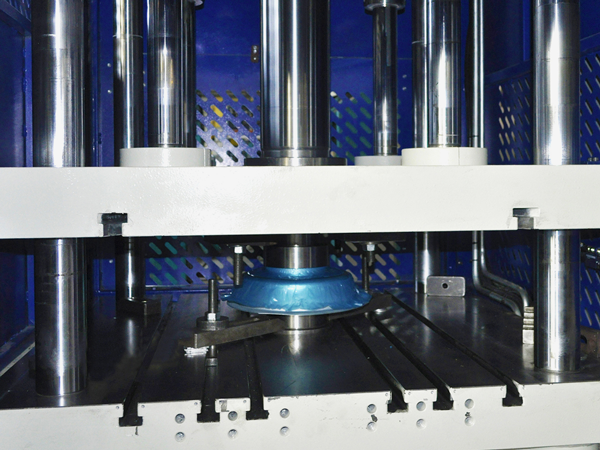

Focusing on the highest standards of production, the Ventilation Systems Company is constantly upgrading its fleet of production equipment. Recently the metalware workshop has been strengthened by putting into operation new hydraulic presses of the column deep draw type with 100-ton capacity each.

The reasons for installation of hydraulic presses included growing of the Vents products production volumes, as well as the desire to create even more comfortable working conditions for the personnel. Indeed, the presses are easy to operate, have compact dimensions, convenient arrangement of the working area and provide the highest level of safety for the specialists who serve them.

The press has a welded frame made of structural steel that can withstand high loads. The working and movable plates are precisely processed and positioned, which makes it possible to obtain products with high accuracy. The ejector roller, located at the top of the plate, speeds up and simplifies removal of parts. Each press is equipped with a two-hand control panel, as well as with an NC/PLC control system with a touch screen that allows controlling the equipment parameters. Protective covers and light barriers also provide increased safety for the operating personnel. All equipment is manufactured in accordance with EC safety directives and is CE certified.

In sight of expansion of inline centrifugal fans production, the new presses will be used for deep drawing of casings and covers for fans of the VKM, VKMz series and other products.