A few years ago, Ventilation Systems introduced to the market a new FlexiVent product, a modular air distribution system. One of the key components of the system is flexible corrugated air ducts made from durable plastics. In view of increasing demand for FlexiVent products with each passing year, the company faced the need in expanding its production capacities and produced assortment range. In order to meet the challenge, one of the production facilities were recently upgraded by addition of a new state-of-the-art production line for manufacturing plastic corrugated air ducts.

The new equipment was made in Italy and in terms of its characteristics, it is deemed to be one of the best in the world. The new line will allow for production of semi-rigid round air ducts with diameters of 63, 75 and 90 mm, as well as flat-oval air ducts with 50х115 mm dimensions.

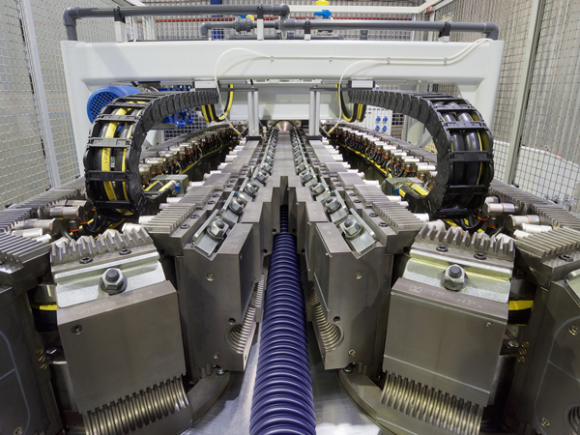

The new production line is fully automated and has a number of design features, which ensure even better workflow productivity and manufactured products quality, as well as convenience of operation for the employees. In particular, cooling system utilized in the new production line allows for high-speed operation up to 14 metres per minute, which is much higher than any similar equipment may offer. Another advantage of the line is that it has feeders for supply of colouring and additive agents to the primary raw materials, which eliminates the need to perform those operations manually and any human factor respectively. Air ducts tightening is also performed in an automatic mode. Moreover, company experts point out significant advantages of accessory equipment design.

Commissioning of the new production line for manufacturing plastic corrugated air ducts will allow company to advance production of semi-rigid and flexible air ducts to a new level in terms of quality and volumes, as well as to broaden its model range according to the market demands.

Note. All photos were taken prior to the announcement of the lockdown in the country.