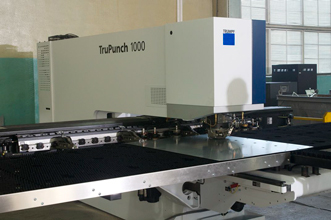

A steady growth of VENTS production capacity makes expanding and upgrading the equipment fleet a basic necessity rather than an option. This time the company's metal-processing shop has received a second high-performance coordinate punching machine made by TRUMPF (Germany).

For the time being the VENTS metal-processing shop has the equipment capability for a complete range of metal processing operations and manufacturing high-quality metal products of any complexity. In particular, the shop equipment includes three AMADA coordinate punching machines and the ultra-modern TRUMPF unit, automated nesting and press cutting centres, welding and roll stretching machines, CNC drilling and thread-tapping machines as well as the unique CNC metal-spinning lathes which help considerably improve fan casing quality by means of rotary rolling - and much more.

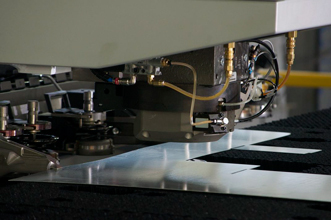

In addition to that the VENTS has recently acquired another high-performance TRUMPF coordinate punching machine for making various shape holes in sheet metal with utmost precision. The coordinate punching machine is also capable of shaping 3D parts such as ventilation grill bars. The TRUMPF unit can process a metal sheet twice the size of the AMADA maximum allowance for cutting parts of most complicated layout geometry. In addition to that its unique 360 degree tool tilting function is a real time saver when it comes to complex operations.

“This year the metal-processing shop performance has doubled while the part processing time has gone down considerably which is mostly due to the commissioning of the new state-of-the-art equipment. The punching machine operation is completely automated for improved quality of the final products as well as metal cutting precision and speed leaving much less space for error than before. In addition to that the unique punching machine design features have resulted in significant energy savings. By and large this new unit has definitely helped us improve the overall production efficiency”, says Yevgeniy Karpenko, metal processing shop manager.