The wide range of VENTS products is made at its full-cycle manufacturing facility featuring state-of-the-art process equipment.

The repair and tool shop (RTS) is tasked with ensuring flawless operation of the entire equipment fleet.

This mission makes the repair and tool shop a critical asset in the VENTS operation scheme. This is where the factory equipment undergoes technical maintenance and repair, the new tools and accessories are made, and the worn-out parts and mechanisms are promptly replaced.

Ensuring trouble-free equipment operation is an absolute must for such a large production facility as the VENTS factory – therefore its toolkit is upgraded on a regular basis.

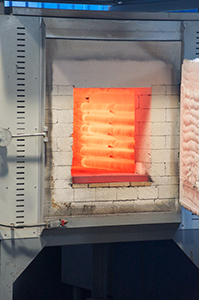

The latest upgrade pack included installation and commissioning of the new high-performance thermal ovens. These machines are used for annealing large-sized tools - in particular, metal press moulds up to 1m wide.

Thanks to the new thermal ovens our engineers are now able to fabricate the necessary size spare parts much quicker than before so that the metal-processing and plastic injection moulding shops as well the entire VENTS production facility can run completely trouble-free.