Being a recognised ventilation leader "Ventilation Systems" never rests on its laurels. The company is constantly upgrading its process equipment fleet and implementing the latest in manufacturing technology. And so far "Ventilation Systems" has been very good at it. Following the latest addition of eight new Haitian injection moulding machines less than a month ago the company has announced the upcoming commissioning of Hilectro XTA Servo robot.

The new piece of equipment installed at the plastic injection moulding shop is intended to complement the thermoplastic processing machine. The robotic manipulator enables automatic operation of the injection moulding machine reducing the time per unit and eliminating the human factor for higher output and quality of fabricated parts. Upon commissioning the Hilectro XTA Servo robot the plastic part fabrication process will become 100% automatic.

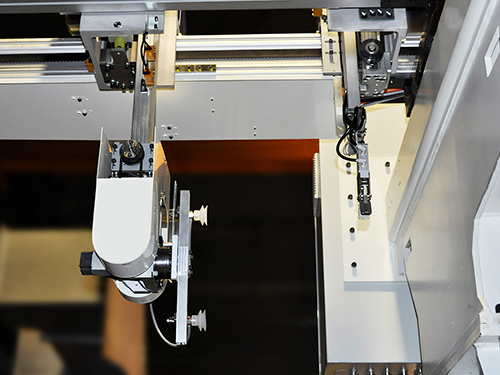

The Hilectro XTA Servo unit is equipped with a three-axis full servo motor as standard (upgradeable to five axes). The Japanese motor ensures quick operation, precise positioning and high control accuracy. The movement along the X and Y axes follows a T-pattern. The Z axis travel is implemented by means of a dual-beam structure which helps reduce power losses and improve stability and rigidity. The low-noise cable drag chain has excellent flexibility and long service life.

The servo drive ensures high positioning precision and excellent controllability.

The servo drive ensures high positioning precision and excellent controllability.

The vacuum gripper for handling finished parts and the mechanical sprue remove help speed up the fabrication process and improve processing quality.

The vacuum gripper for handling finished parts and the mechanical sprue remove help speed up the fabrication process and improve processing quality.

What the experts say:

"The test run of the servo robot has surpassed our expectations!"

Head of Plastic Injection Moulding Shop No. 1

Hilectro XTA Servo robot is a state-of-the-art multi-function unit which can help automate most of our operations. The unit has two grippers: a vacuum unit for handling finished parts and a mechanical sprue remover which considerably reduce the time per unit. The robot has an built in fail-safe system to protect from input errors ensuring a high level of operator protection. The robot has passed the trials with flying colours surpassing our expectations. Its quick, precise and 100% repeatable movements leave no space for human error and manufacturing defects.