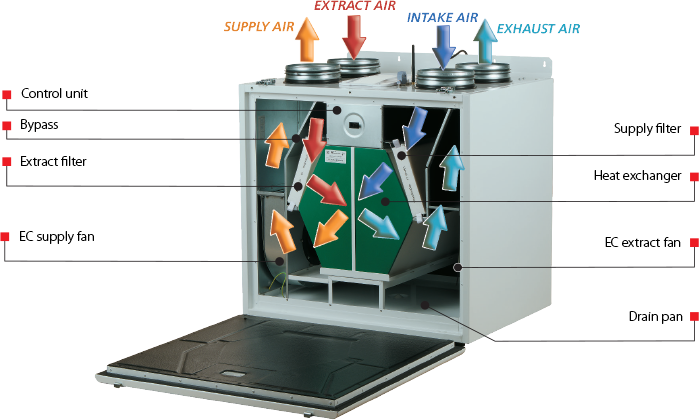

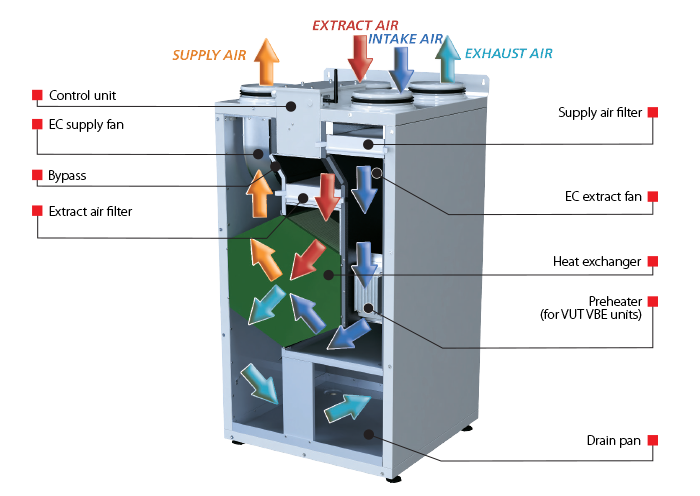

The air-handling units are the fully featured ventilation units with heat recovery for air filtration, fresh air supply and stale air extraction.

Casing

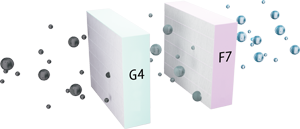

Filter

Fans

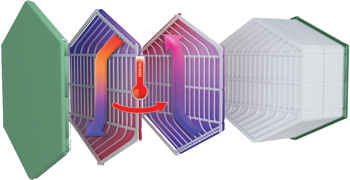

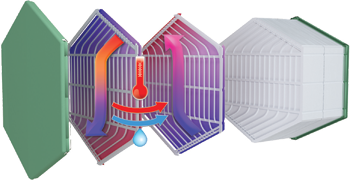

Heat exchanger

Unit Design

VUT 350 VB EC

VUT(E) 250 VBE EC L/R

Bypass

Аutomation

Freeze protection

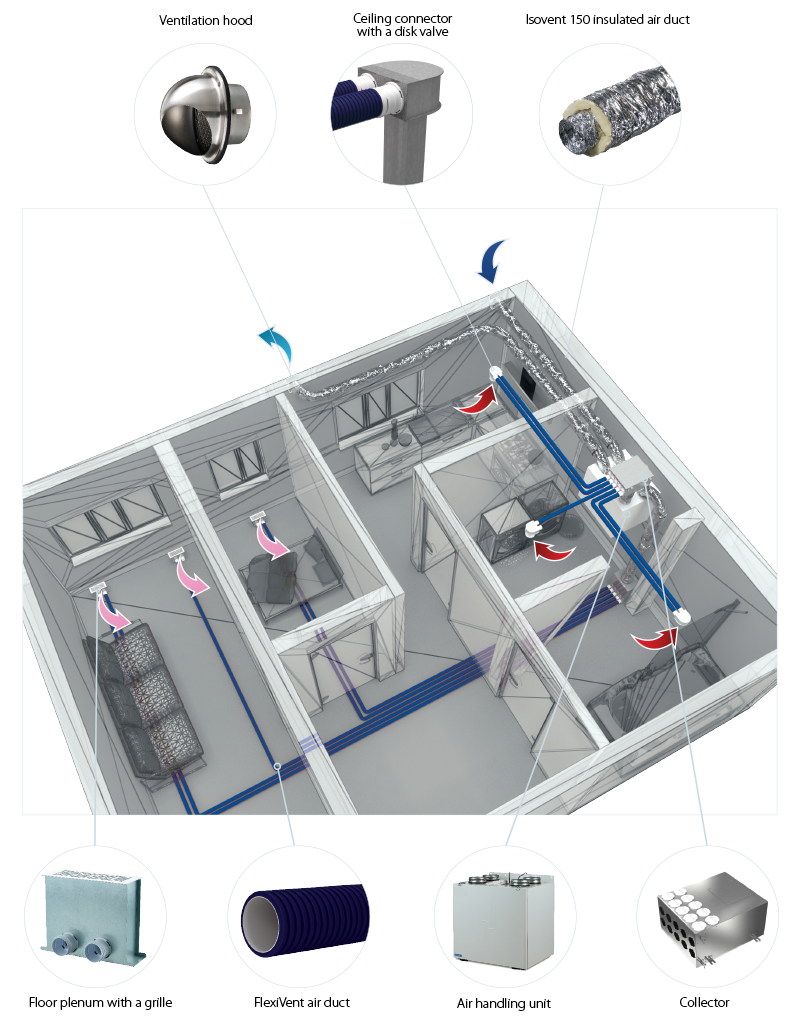

Mounting

Application options

| Lineup Vents VUT VB EC | Connected air duct size, mm | Rated power, W | Maximum airflow, m3/h | Service side | Control system | Reheater | Preheater | BMS protocol |

|---|---|---|---|---|---|---|---|---|

| 125 | 57 | 200 | Universal | A21 | Optional | Optional | ModBus | |

| 125 | 57 | 200 | Universal | A14 |

|

|

|

|

| 125 | 57 | 200 | Universal | A21 | Optional | Optional | ModBus | |

| 125 | 57 | 200 | Universal | A14 |

|

|

|

|

| 160 | 180 | 390 | Right | A21 | Optional | Optional | ModBus | |

| 160 | 180 | 390 | Left | A21 | Optional | Optional | ModBus | |

| 160 | 180 | 390 | Right | A14 |

|

|

|

|

| 160 | 180 | 390 | Left | A14 |

|

|

|

|

| 160 | 180 | 390 | Right | A21 | Optional | Built-in | ModBus | |

| 160 | 180 | 390 | Left | A21 | Optional | Built-in | ModBus | |

| 160 | 178 | 450 | Universal | A21 | Optional | Optional | ModBus | |

| 160 | 178 | 450 | Universal | A14 |

|

|

|

|

| 160 | 169 | 420 | Universal | A21 | Optional | Optional | ModBus | |

| 160 | 169 | 420 | Universal | A14 |

|

|

|

|

| 200 | 350 | 692 | Universal | A21 | Optional | Optional | ModBus | |

| 200 | 350 | 692 | Universal | A14 |

|

|

|